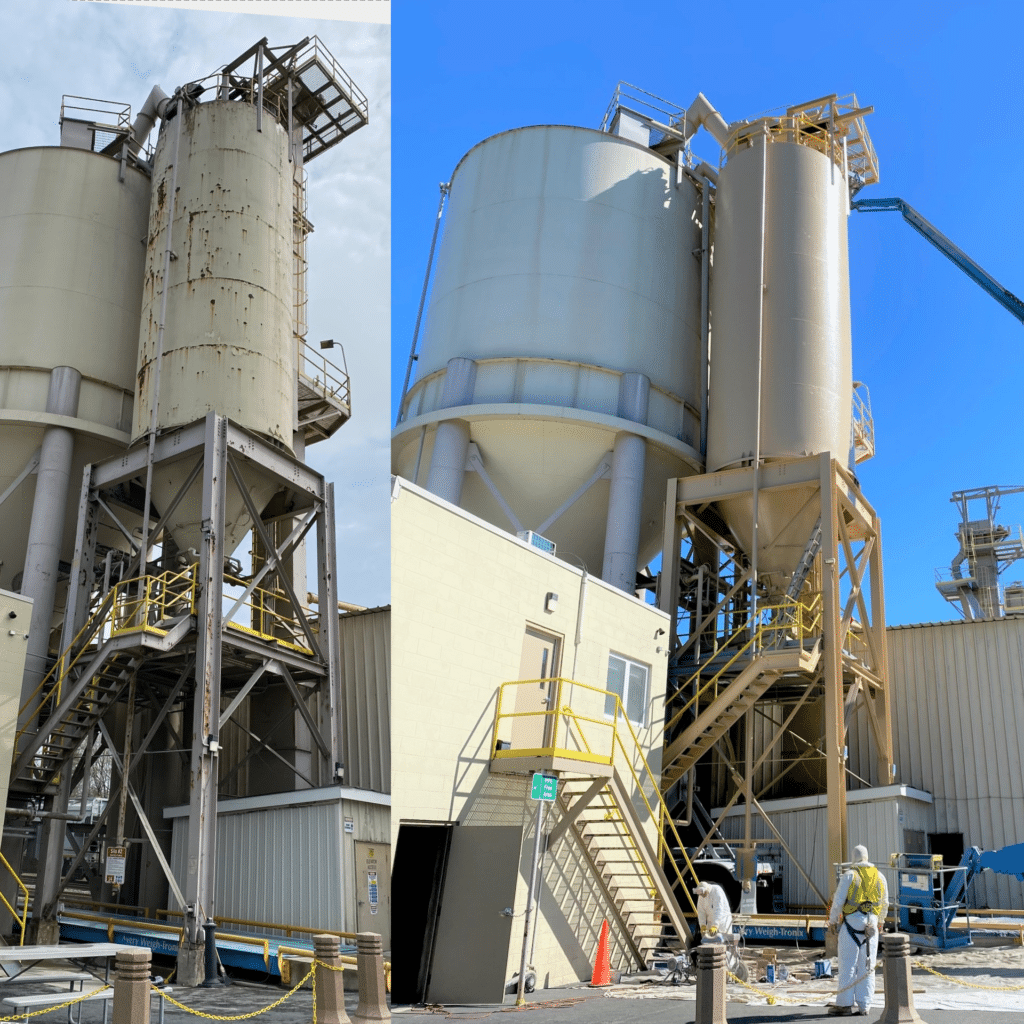

Industrial Equipment Painting to Protect Machinery

Industrial equipment painting is more than just a maintenance task, it’s a crucial investment in the longevity of your heavy machinery.

Specialized coatings provide a robust shield against corrosion, wear, and the harsh realities of industrial environments, enhancing both performance and durability. Beyond mere looks, these protective layers also contribute to a safer and more efficient workplace.

Opting for professional painting services makes sure the job is done properly and safely, while ultimately boosting your machinery’s operational integrity and value. All while improving safety and reducing environmental impact.

Understanding Heavy Industrial Equipment Painting

Heavy industrial equipment requires regular maintenance, including painting, to ensure efficiency. Let’s run through the benefits of industrial equipment painting below.

Benefits of Regular Painting

Regular painting of industrial equipment is crucial for several reasons. It not only enhances the appearance but also serves as a protective layer against the elements.

A significant benefit to painting heavy equipment is its ability to keep equipment cooler, reducing reliance on costly cooling systems.

Painting and Corrosion Prevention

A well-applied coat of (the correct) paint acts as a barrier against moisture, chemicals, and environmental factors that contribute to corrosion. Moreover, proper cleaning and preparation of surfaces before painting are crucial as well.

Selecting the Right Paint for Industrial Equipment

The choice of paint is paramount when it comes to industrial equipment painting. Factors to consider include the operating environment, the material of the equipment, and the desired longevity of the protective coat. Paints with reflective properties are often recommended as they can reflect heat and reduce cooling needs.

At McLean Company, you can reach out to our experts for help understanding which paint would work best for your equipment.

Preparing for the Painting Process

Preparation is crucial for the success of industrial equipment painting. It ensures maximum adhesion, durability, and a high-quality finish.

From surface preparation techniques to cleaning and degreasing, each step must be meticulously followed to protect and maintain the industrial equipment.

Surface Preparation Techniques

Surface preparation is the most important step in painting industrial equipment, as it directly impacts the coating’s lifespan. Techniques vary based on the condition of the equipment:

- Abrasive blasting strips old coatings and provides a clean, rough profile for paint adherence.

- Power tool cleaning removes loose rust and paint when abrasive blasting isn’t feasible.

The choice of method depends on the specific requirements of the industrial equipment to be painted.

Cleaning and Degreasing Equipment

Before beginning any painting process, every inch of the equipment should be thoroughly cleaned and degreased. This can involve:

- Utilizing industrial-grade solvents or degreasers to break down contaminants.

- Applying pressure washing to remove residues from equipment surfaces.

No contaminants must be left on the equipment, as they can compromise the paint’s integrity.

Removing Old Paint and Rust

The longevity of a new paint job can be compromised by existing defects. Therefore:

- Scraping or sanding techniques are often employed to meticulously remove old paint.

- Chemical strippers can be utilized to lift and dissolve paint without damaging the substrate.

- Rust removal is essential, as rust can propagate under new paint, leading to premature failure of the coating.

The Painting Procedure

The painting procedure for heavy industrial equipment is a meticulous process, essential for protection and aesthetics. It involves stages tailored to ensure maximum adhesion, durability, and quality of finish.

Primer Application

The primer stage is foundational to protect metal surfaces against corrosion and ensure the adherence of subsequent paint layers.

Heavy industrial equipment requires a high-quality, rust-inhibitive primer. It is typically applied after thorough surface preparation for the primer to bond effectively.

Paint Application Methods

There are several methods for applying paint to heavy industrial equipment, including spraying, brushing, and rolling. For large surfaces, spraying is the most efficient, providing a uniform coat and the ability to reach difficult spaces.

Airless sprayers work well, as they handle thick, protective paints. Precision is key in this method to avoid runs and ensure even coverage.

Finishing Coats and Detailing

Finishing coats may include a high-performance topcoat that resists UV light, harsh weather, and chemical exposure. Detailing involves the application of safety colors, logos, or other markings necessary for operational purposes.

This step is both aesthetic and functional, often utilizing contrasting colors for visual impact and safety compliance.

Maintenance and Touch-Ups

Regular maintenance and timely touch-ups are critical in preserving the integrity and appearance of heavy industrial equipment paint jobs. These steps not only extend the lifespan of the equipment but also ensure that it operates at peak performance.

Routine Inspection

Frequency and Attention to Detail: Equipment should be inspected regularly. Key aspects to check include paint integrity, coating uniformity, and signs of wear or corrosion.

Inspection Checklist:

- Surface Cleanliness: Ensure the surface is free of contaminants.

- Paint Coherence: Look for signs of peeling or chipping.

- Protective Layer Integrity: Assess if the protective paint layer is intact.

- Signs of Rust: Identify any rust formation early on.

Repairing Damaged Paint Jobs

For significant damage, a professional assessment may be necessary to determine if a complete repaint is more cost-effective compared to multiple touch-ups.

This will make sure that the heavy industrial equipment sustains its functionality and aesthetic value for a longer period.

McLean Company: Industrial Equipment Painting Experts

McLean Company stands out as a seasoned expert in the industrial painting sector, with more than 35 years of experience.

This longevity reflects a deep understanding of the complexities involved in industrial machine & equipment painting, earned through years of service in Massachusetts and surrounding areas.

The team at McLean Company is not just any contractor; they are professional industrial painting contractors dedicated to the highest standards of quality and durability.

We approach each project with a confident and knowledgeable mentality, ensuring clients receive the best results through expert guidance and services without any hidden costs.

Contact McLean Company at 978-774-4330 or fill out the online form and we’ll get back to you.