Flooring in commercial and industrial facilities is more than a surface. It protects your concrete, supports daily operations, and impacts safety and maintenance costs. If you are considering hiring a resinous flooring contractor, it is important to understand what resinous systems are and how they perform in demanding environments. For businesses in Boston, MA and surrounding areas, resinous flooring offers long term durability when installed correctly. You can explore how these systems are applied in commercial and industrial settings by reviewing our resinous flooring solutions.

In this guide, we will cover:

- What resinous flooring is and how it works

- The primary products used in resin systems

- What a resinous flooring contractor actually does

- How to choose the right system for your facility

- Installation, maintenance, and long term performance

Why Resinous Flooring Is a Smart Investment for Commercial Facilities

Concrete alone is not built to withstand years of industrial abuse without protection. Forklift traffic, pallet movement, chemicals, moisture, and heavy equipment gradually wear down untreated slabs. Over time, this leads to cracking, dusting, staining, and safety concerns.

Resinous flooring systems are designed to transform bare concrete into a seamless, high performance surface that resists damage and extends slab life. For property managers and facility owners in Boston, MA and surrounding areas, this means fewer operational disruptions and better long term value.

Key advantages include:

- Durability Under Heavy Traffic

Resin systems are engineered to handle constant equipment movement and foot traffic without rapid wear. - Chemical and Moisture Resistance

Properly installed systems resist oils, water, and many industrial chemicals that would otherwise damage concrete. - Improved Workplace Safety

Seamless finishes and slip resistant additives help reduce trip and slip hazards. - Lower Maintenance Requirements

Without joints or grout lines, resinous floors are easier to clean and maintain. - Extended Concrete Lifespan

Protective coatings shield the slab from corrosion, moisture intrusion, and surface deterioration.

When installed by experienced professionals, resinous flooring becomes a long term asset rather than a short term fix.

4 Core Products Used in Resinous Flooring Systems

Resinous flooring is not a single material. It is a layered system built using specific products selected for performance and environmental demands. Below are the four primary components typically involved.

1. Epoxy Systems

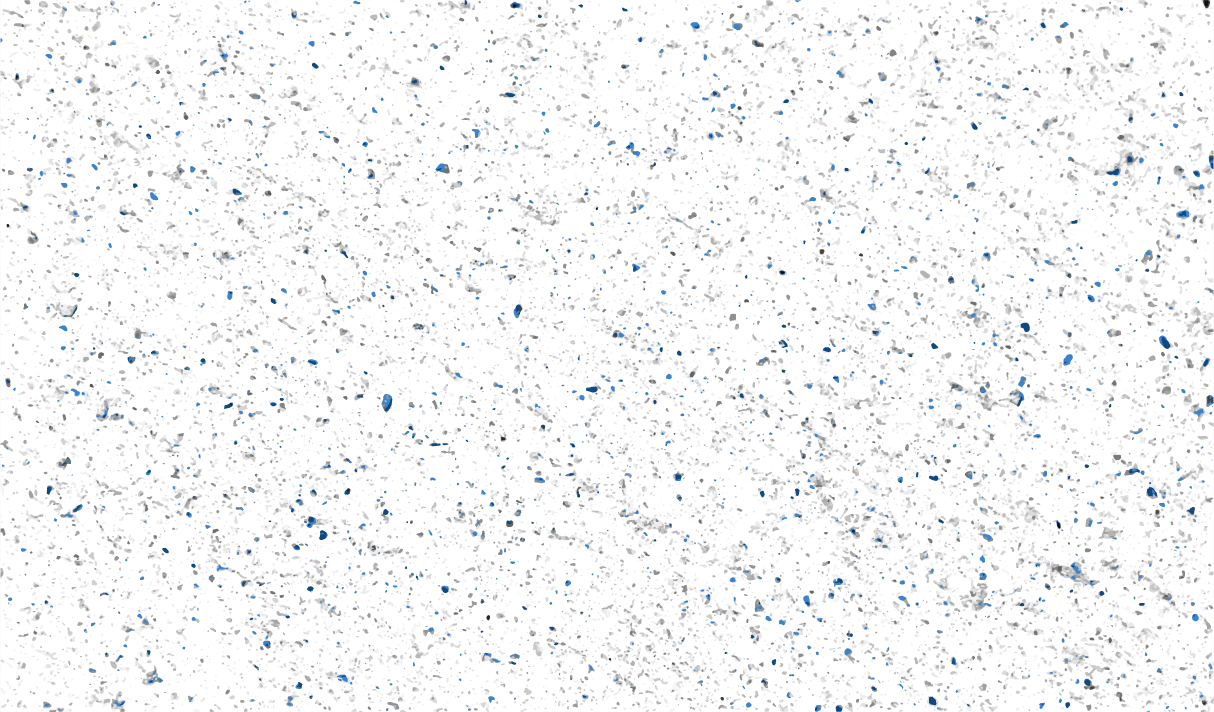

Epoxy flooring is one of the most common resinous solutions used in commercial and industrial facilities.

Epoxy systems typically include:

- A primer to bond with properly prepared concrete

- A body coat to build thickness and strength

- A topcoat for added chemical and abrasion resistance

Epoxy provides strong adhesion, compressive strength, and a seamless finish that performs well in warehouses, manufacturing facilities, and distribution centers.

2. Urethane and Cement Urethane Systems

Urethane systems offer additional flexibility and resistance to thermal shock.

They are often selected for:

- Areas exposed to temperature changes

- Environments requiring higher impact resistance

- Facilities with demanding wash down procedures

Cement urethane systems can withstand significant abuse while maintaining durability and structural integrity.

3. Polished Concrete Systems

Polished concrete enhances the performance of existing slabs through mechanical grinding and densification.

The process includes:

- Surface grinding

- Application of densifiers

- Progressive polishing for durability

As certified Husqvarna installers, we use proven methods to strengthen and refine concrete surfaces for long term use.

4. Protective Topcoats and Sealers

Topcoats and sealers enhance system performance and longevity.

They may provide:

- UV stability

- Additional chemical resistance

- Enhanced cleanability

- Slip resistance

Selecting the correct combination of materials is critical. A qualified contractor evaluates operational demands before recommending a system.

5 Essential Steps a Resinous Flooring Contractor Should Follow

Installing resinous flooring is a technical process that requires precision and discipline. Below are the five critical steps every professional contractor should follow.

1. Concrete Evaluation

Every project begins with assessing the existing slab.

This includes:

- Moisture testing

- Identifying cracks or surface defects

- Reviewing previous coatings or contamination

Skipping this step increases the risk of adhesion failure.

2. Surface Preparation

Preparation is often the most important stage of installation.

This may involve:

- Mechanical grinding

- Shot blasting

- Crack repair

- Removal of failing coatings

Proper profiling ensures strong bonding between the concrete and resin system.

3. System Design and Material Selection

No two facilities are identical. A warehouse in Boston, MA and surrounding areas may have different needs than a food processing facility or office building.

Contractors must consider:

- Traffic levels

- Chemical exposure

- Moisture conditions

- Safety requirements

- Operational scheduling

The goal is to design a flooring system tailored to the environment.

4. Professional Installation

Resin materials require controlled mixing, timing, and application.

Installation typically includes:

- Applying primers

- Installing body coats

- Broadcasting aggregate if needed

- Applying protective topcoats

- Striping or marking traffic lanes

Environmental conditions must be monitored to ensure proper curing.

5. Final Inspection and Quality Control

After installation, the system should be inspected carefully.

Quality checks confirm:

- Consistent thickness

- Proper adhesion

- Clean transitions

- Accurate striping

Attention to detail at this stage protects the long term performance of the floor.

How to Choose the Right Resinous Flooring Contractor

Selecting the right contractor is just as important as choosing the right product. Resinous flooring systems require commercial and industrial expertise.

When evaluating contractors, consider:

- Experience in Commercial and Industrial Environments

Contractors should focus on large scale facilities rather than residential work. - Safety Certifications

OSHA certification and comprehensive safety practices are essential. - Knowledge of Trusted Manufacturers

Working with established brands such as Sherwin-Williams, PPG, Rust-Oleum, General Polymers, Sika, and Duraflex ensures quality materials. - Clear Communication

Professional contractors return calls promptly and provide clear project timelines. - Detailed Proposals

A reliable contractor outlines preparation methods, material types, and installation steps clearly.

Facilities in Boston, MA and surrounding areas benefit from partnering with contractors who understand operational needs and prioritize disciplined execution.

Cost, Maintenance, and Long Term Flooring Solutions

Resinous flooring is an investment. While upfront costs vary based on system thickness, preparation requirements, and square footage, long term value is often significantly higher than untreated concrete.

Factors affecting cost include:

- Condition of the existing slab

- Required preparation work

- Thickness of the system

- Environmental conditions

- Operational constraints

Maintenance is typically straightforward. Routine cleaning and periodic inspections help extend performance life. Because resinous systems are seamless, they reduce areas where debris and contaminants can accumulate.

Over time, facilities often experience:

- Reduced repair frequency

- Lower maintenance labor

- Improved operational efficiency

- Enhanced safety conditions

For property owners in Boston, MA and surrounding areas, these long term benefits outweigh short term savings from less durable alternatives.

Why Professional Installation Matters

Resinous flooring is not a do it yourself solution. Improper preparation, incorrect mixing ratios, or poor application techniques can lead to peeling, bubbling, or premature wear.

Professional installation ensures:

- Correct surface profiling

- Accurate moisture assessment

- Proper product selection

- Controlled application conditions

- Thorough final inspection

At McLean Company, we focus on disciplined execution, safety, and long term performance. Our experienced foremen and skilled field personnel specialize in commercial and industrial environments, bringing structured planning and attention to detail to every project.

Protect Your Facility with the Right Resinous Flooring System

Resinous flooring is more than a coating. It is a system designed to protect your concrete, improve safety, and support demanding operations. Understanding the products involved and the process a resinous flooring contractor follows allows you to make informed decisions for your facility.

If your commercial or industrial property is experiencing surface wear, cracking, or coating failure, now is the time to act. McLean Company provides structured planning, experienced crews, and professional installation for facilities in Boston, MA and surrounding areas. To discuss your project and explore the right solution for your building, contact us today.