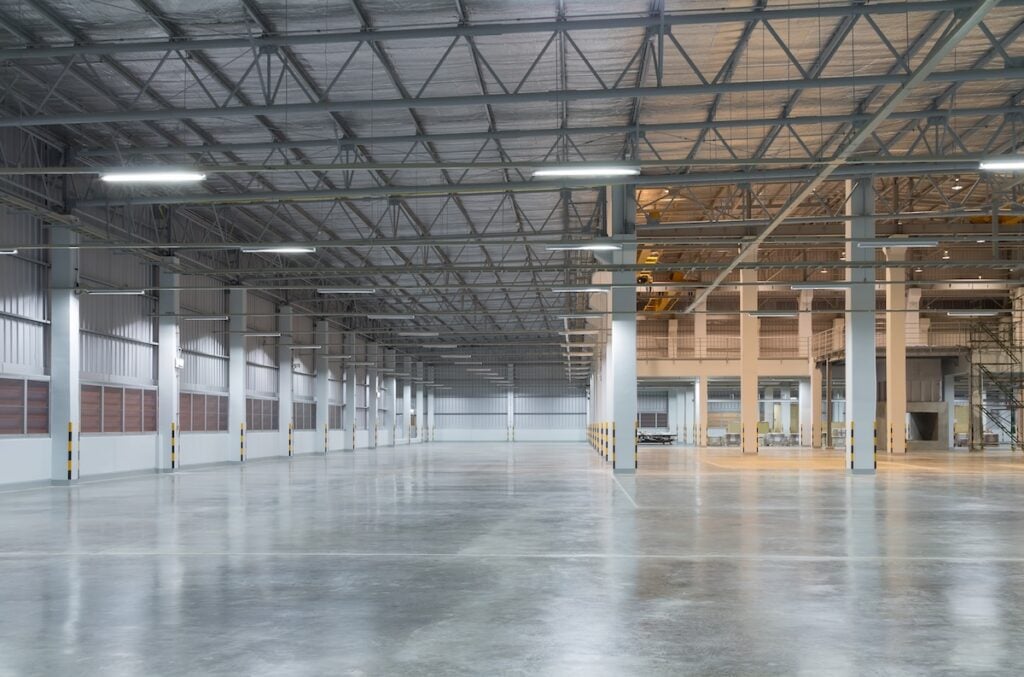

Undertaking a large-scale epoxy flooring installation project can transform a commercial or industrial space, offering durability, aesthetic appeal, and ease of maintenance. Given the complexity involved, understanding how to design, plan, and budget for such an expansive project is essential. Epoxy floors provide not only an elegant finish but also enhance safety and longevity in environments with heavy foot or machinery traffic. For detailed assistance on similar projects, check out our comprehensive commercial flooring services that can guide you through the process smoothly.

In this guide, you will learn:

- The importance of thorough design and planning in large-scale epoxy flooring installations

- Key steps to prepare your space and select appropriate materials

- How to create a realistic budget and timeline that match your project goals

- Maintenance considerations for preserving your epoxy flooring over time

- Tips to avoid common pitfalls and ensure your project’s success

Why Large-Scale Epoxy Flooring Installation Requires Strategic Planning

Installing epoxy flooring on a large scale is fundamentally different from smaller applications because of the sheer volume of materials, labor, and preparation involved. Every aspect, from floor condition to curing time, can impact the outcome. Strategic planning is crucial to maximize the benefits of epoxy flooring, which is prized for its high resistance and vibrant finish. Businesses seeking expert epoxy solutions can rely on professional epoxy flooring services in Warwick, RI to manage large-scale installations efficiently and effectively.

- Durability Requirements: Large spaces often undergo heavy use, requiring epoxy formulations tailored for wear resistance and impact tolerance.

- Surface Preparation: Ensuring the substrate is clean, dry, and structurally sound is more complex for larger floor areas.

- Application Techniques: Specialized equipment or multiple teams may be necessary to maintain a uniform finish and efficient workflow.

- Scheduling Impact: Phased installation may be required in operating facilities to minimize downtime.

- Cost Management: Economies of scale can influence material costs, but labor and downtime expenses need careful forecasting.

7 Steps to Design, Plan, and Budget Your Large-Scale Epoxy Flooring Installation

Organizing a successful large-scale epoxy flooring project requires a systematic approach. Breaking it down into clear steps enables you to track progress and prevent costly oversights.

1. Assess the Existing Floor and Site Conditions

Begin with a detailed analysis of the current flooring and environment.

- Surface Integrity: Check for cracks, moisture levels, and contaminants that might affect adhesion.

- Load and Usage Patterns: Understand how the space is used to choose appropriate epoxy strength and finish.

- Obstructions: Identify machinery, walls, or fixtures that could complicate installation.

2. Define Your Functional and Aesthetic Goals

Clarify what performance and look you want from the epoxy flooring to guide material selection and treatments.

- Slip Resistance: Decide if you need special additives or textures for safety compliance.

- Color and Finish: Choose colors and sheens that match branding or lighting needs.

- Chemical Resistance: Ensure coating formulas can withstand any chemicals present in your facility.

3. Select the Right Epoxy Material System

Not all epoxy systems are created equal; select based on project requirements. This guide on acid-resistant flooring explains when enhanced chemical resistance is necessary and how it can significantly extend the lifespan of large-scale epoxy flooring installations.

- Standard Epoxy: Good for general use with moderate durability.

- High-Build Epoxy: Thick layers ideal for uneven surfaces or higher protection.

- Multi-Component Systems: Combining primers, fillers, and topcoats for tailored results.

4. Develop a Detailed Installation Plan

Layout a stepwise schedule coordinated with facility operations to minimize disruptions. Companies planning major flooring upgrades can benefit from trusted epoxy flooring services in Hartford, CT that understand how to execute large projects without disrupting daily operations.

- Phased Work: Segment large areas to allow sections to cure without halting all activity.

- Workforce Coordination: Plan team sizes and shifts considering the project’s timeline.

- Equipment Logistics: Ensure all necessary machinery and materials are staged efficiently.

5. Calculate Budget and Resource Allocation

Create a comprehensive financial plan incorporating all cost elements.

- Materials: Quantity, quality, and potential wastage.

- Labor: Skilled installers, supervision, and overtime.

- Downtime Impact: Lost productivity during installation phases.

6. Conduct Surface Preparation Thoroughly

Effective substrate preparation is vital for epoxy adhesion and longevity.

- Cleaning: Remove dust, oils, and existing coatings.

- Repairs: Fix cracks, holes, and uneven spots using suitable fillers.

- Profiling: Mechanical grinding or shot blasting to create the right texture.

7. Execute Installation and Quality Control

Supervise the application carefully to ensure adherence to specifications.

- Consistent Mixing: Prepare epoxy resin and hardener in specified ratios.

- Application Speed: Working within pot life and curing windows.

- Inspection: Monitor for defects, bubbles, or unevenness and address immediately.

Extended Planning Considerations for Large-Scale Epoxy Flooring

In sprawling floor projects, additional factors influence success beyond the basic steps. These integrate operational realities, environmental conditions, and long-term maintenance strategies. This overview of concrete floor finishes provides valuable context for deciding whether epoxy is the best solution for your facility’s needs.

Environmental Control

Temperature and humidity critically affect epoxy curing; thus, maintaining the right environment is necessary.

Installing temporary climate controls or adjusting work schedules to daytime or cooler months can improve outcomes.

Safety Protocols

Handling epoxy chemicals requires protective equipment and ventilation.

Implementing comprehensive safety training and monitoring exposure levels safeguard workers and meet regulatory standards.

Maintenance Planning

Longevity depends on maintaining the epoxy’s integrity and appearance.

Develop schedules for regular cleaning, inspections, and repair of surface damages to extend the flooring’s functional life.

Supplier and Contractor Selection

Choosing experienced suppliers and certified installation contractors ensures access to quality materials and professional workmanship.

Request references and review portfolios of their large-scale projects to verify competence.

Frequently Asked Questions About Large-Scale Epoxy Flooring Installation

Addressing common queries helps clarify concerns and smooth the decision-making process.

- How long does the installation of large-scale epoxy flooring typically take? Installation time depends on area size, substrate conditions, and curing time but generally spans several days to weeks.

- Can epoxy flooring be installed while the facility remains operational? Yes, through phased installation and scheduling during off-hours, disruptions can be minimized.

- What maintenance is required after installation? Regular cleaning with non-abrasive materials and timely repairs of any surface damage are recommended.

- Are there any environmental restrictions with epoxy materials? Disposal and VOC content regulations vary; using low-VOC products and proper waste management is essential.

- Is epoxy flooring cost-effective for large areas? Though initial costs are higher than some alternatives, durability and low maintenance make it economical long term.

Taking the Next Step to Your Epoxy Flooring Project

Large-scale epoxy flooring installation can significantly upgrade your space with the right design, planning, and budgeting. By following these steps and considering the broader project needs, you ensure a lasting and visually compelling floor surface. When you are ready to move forward, McLean invites you to contact us today for expert advice and service tailored to your facility’s unique requirements. Our team is committed to delivering exceptional commercial flooring solutions that meet your expectations in quality and performance. Facilities ready to move forward can explore professional epoxy flooring services in Braintree, MA to get expert guidance tailored to their specific space.